Pre-Solves

Tank Cleaning Chemicals

As the name implies, Pre-Solves are used to soften and/or solubilize stubborn materials prior to washing. At the end of their chemical journey resins, polymers, monomers, etc., begin to polymerize. Often, a solvent with similar characteristics to the original carrier solvent, is capable of thinning out the tacky or hardened material. Other times, however, more aggressive formulated materials are required. Here are just a few examples.

Resins & Lacquers

These materials tend to get tacky quickly, and while not so difficult to remove, they can be super abrasive if a pre-solve step is skipped. Hot-vat solutions that concentrate emulsified resins do not last as long between re-charges, hence cleaning cost per tank may actually increase. John-Henry LIQUI-FIRE RX® solves these issues. For best results, see Standard Operating Procedures.

4-ADPA

This chemical intermediate is used in manufacturing of aniline dyes, rubber and fuels, and even lubricants. And it does not play nice when it is time to wash the tank. A specially designed John-Henry procedure, along with LIQUI-FIRE RXE® pre-solve, yields a clean tank in about an hour. For best results, see Standard Operating Procedures.

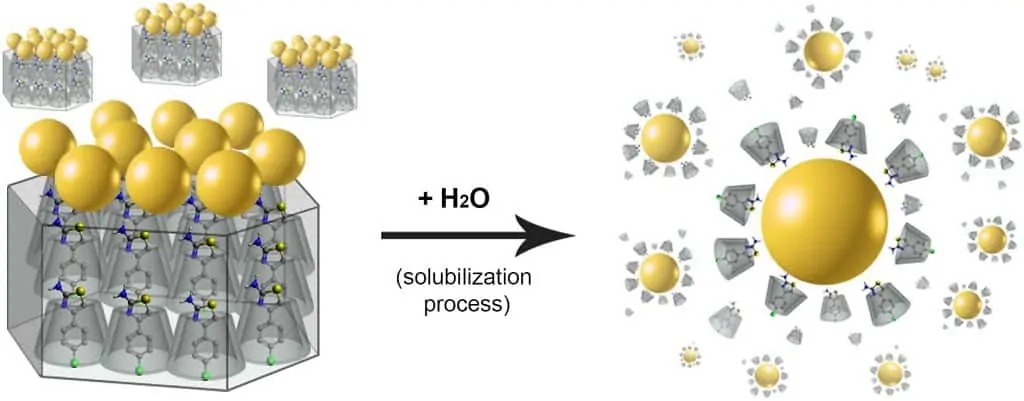

Floc & Friction Reducers

a.k.a., “Elephant Snot” – These water treatment polyacrylamides are used to coagulate solids that are suspended in liquids, or in the petroleum industry to assist in oil recovery. They are water-soluble. and very easy to clean. Until they damage your tank wash. Floc & FR have some baggage – the polymer swells when water is added. The more you rinse the more it swells, at times generating hundreds of extra gallons of wastewater. Then it settles in the drains and hardens, requiring expensive clean-out work. A specially designed John-Henry procedure, along with TRIPLE PLAY® pre-solve, makes for an easy time of it, and the total wash time is only 70 minutes from start to finish – and to insure the integrity of your stainless steel, our process does not contain salt, bleach, or sulfuric acid disguised as something else. For best results, see Standard Operating Procedures.

Latex

Many variables make this material one of the hardest to clean. There are many types, but for this discussion, let’s concentrate on the most common and difficult to clean – SBR latex (Styrene Butadiene Resin). It is a bear to remove by conventional means, but with a specially designed John-Henry procedure, along with M-PINGE 200® vapor impingement pre-solve, you won’t waste valuable time on a wash bay. Latex is a lattice, and penetrating it with a powerful solvent will destroy its elastomeric properties. This can be accomplished at a heating station, away from your wash bays. Once the vapor impingement phase is complete, the tank is taken to the wash rack for a normal, short-duration latex wash. For best results, see Standard Operating Procedures.

Isocyanates

All forms of isocyanates, whether TDI (a poison in its raw state) or MDI, can all be treated the same when they are already set up. Even when these materials are not yet hardened, they are still easily cleaned with a specially designed John-Henry procedure, and M-PINGE 99® pre-solve. Only 15 – 20 gallons of this material is used along with steam via the tank’s coils. M-PINGE 99 releases primary amine vapors, melting away the isocyanate. After draining the spent material, and performing several hot water rinses, the tanks are 100% clean and have a “new look.” For best results, see Standard Operating Procedures.

Or fill out our Quick Call Request form below.