WR03 Systems

Wastewater Technologies

Water Purification

The WRO3 NB represent the latest advancements in water treatment technology. These units utilize patented Nanobubble technology to facilitate increase dissolved oxygen while injecting high levels of ozone via a venturi to provide advanced oxidation designed to reduce levels of organic and inorganic contaminants. The unique ability of nanobubbles to remain in the solution provides increased contact with the loading in the water volume.

Applications Included:

| Tank Wash Water | FPI Waste Water |

| Emulsified Oils | Metal Working Fluids |

| Ink Waste Water | Marine Waste Waters |

| Wash Water Discharge | Plating Wastes |

| Wash Water Recycling | Latex Waste Water |

| Agriculture Waste | Soluble Solutions |

FEATURES

✅ Fully automated for simple operation

✅ Rugged all stainless steel construction

✅ Dual Bag Filter filtration system with auto-monitoring

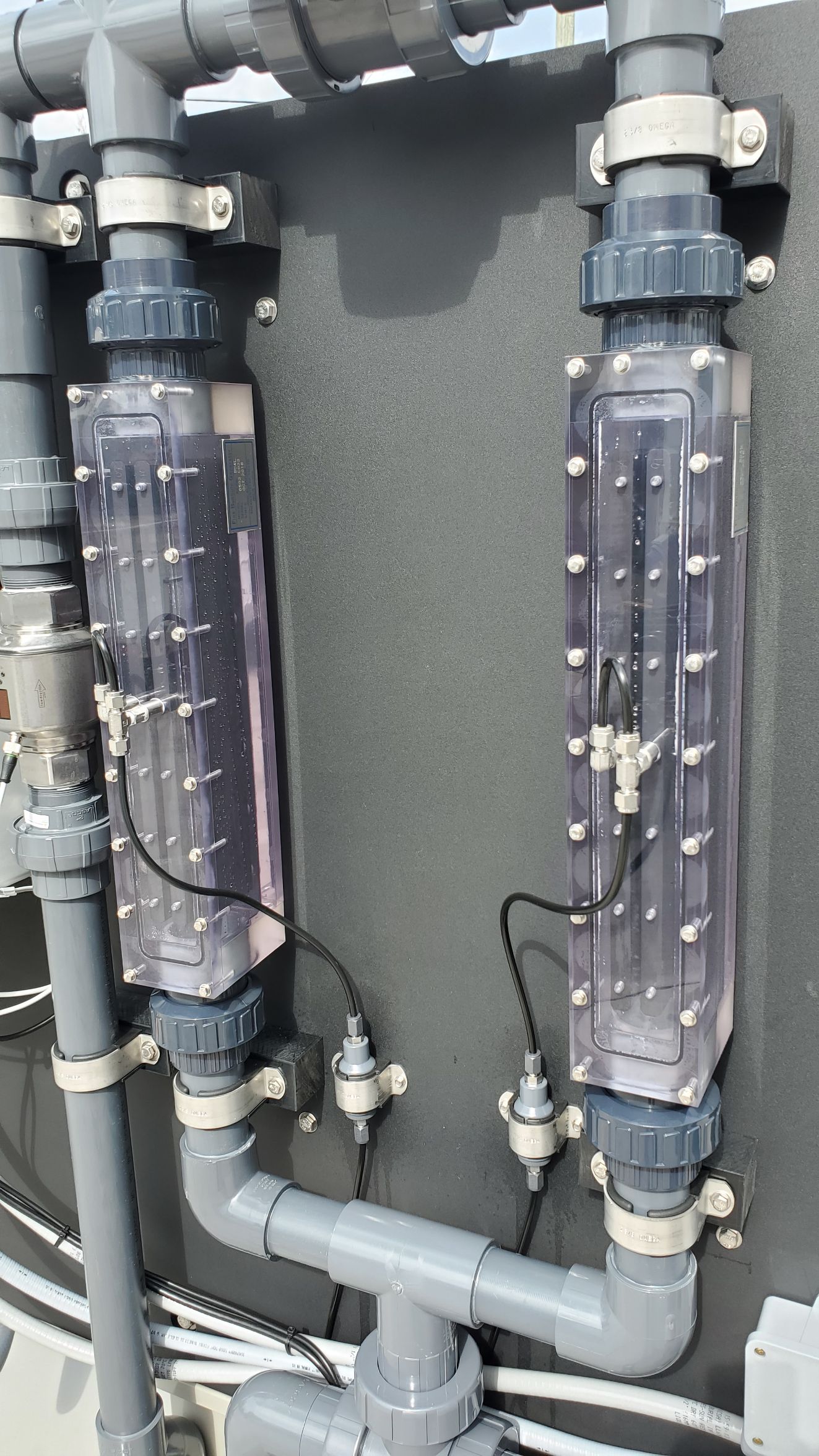

✅ Nanobubble Technology oxygen aeration 10-97 nm bubble size

✅ Venturi ozone injection

✅ Self-Generation of 93% pure oxygen used in system

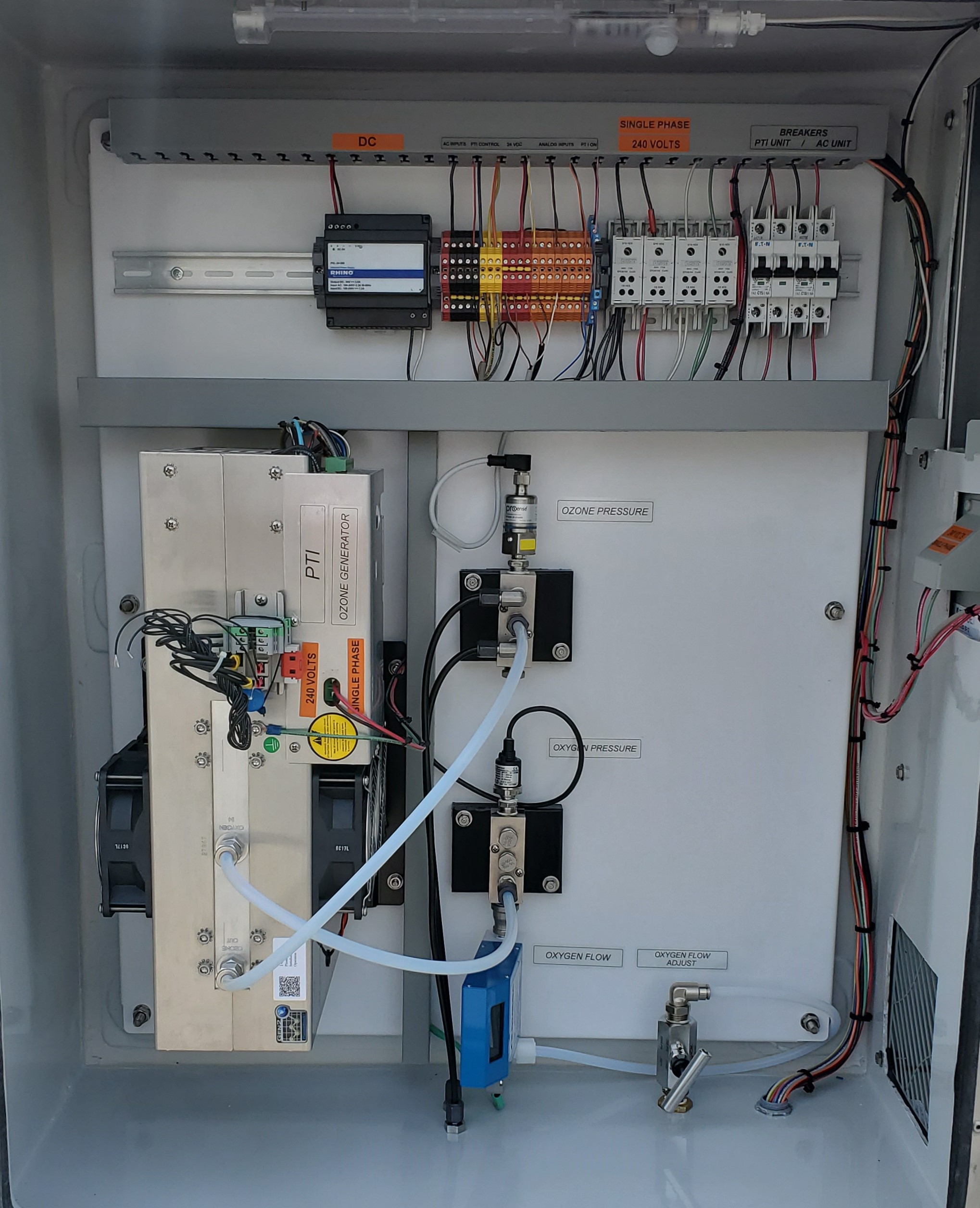

✅ Plasma ozone generation technology

BENEFITS

✅ Cost effective

✅ Energy efficient

✅ ORP monitoring and control

✅ Enhanced water quality for reuse and/or evaporation

OPTIONS

✅ PH Control option available

✅ Dissolved Oxygen monitoring available

✅ Pre And Post treatment systems available

✅ Advanced Oxidation Treatment available

Or fill out our Quick Call Request form below.

Plasma ozone generation technology

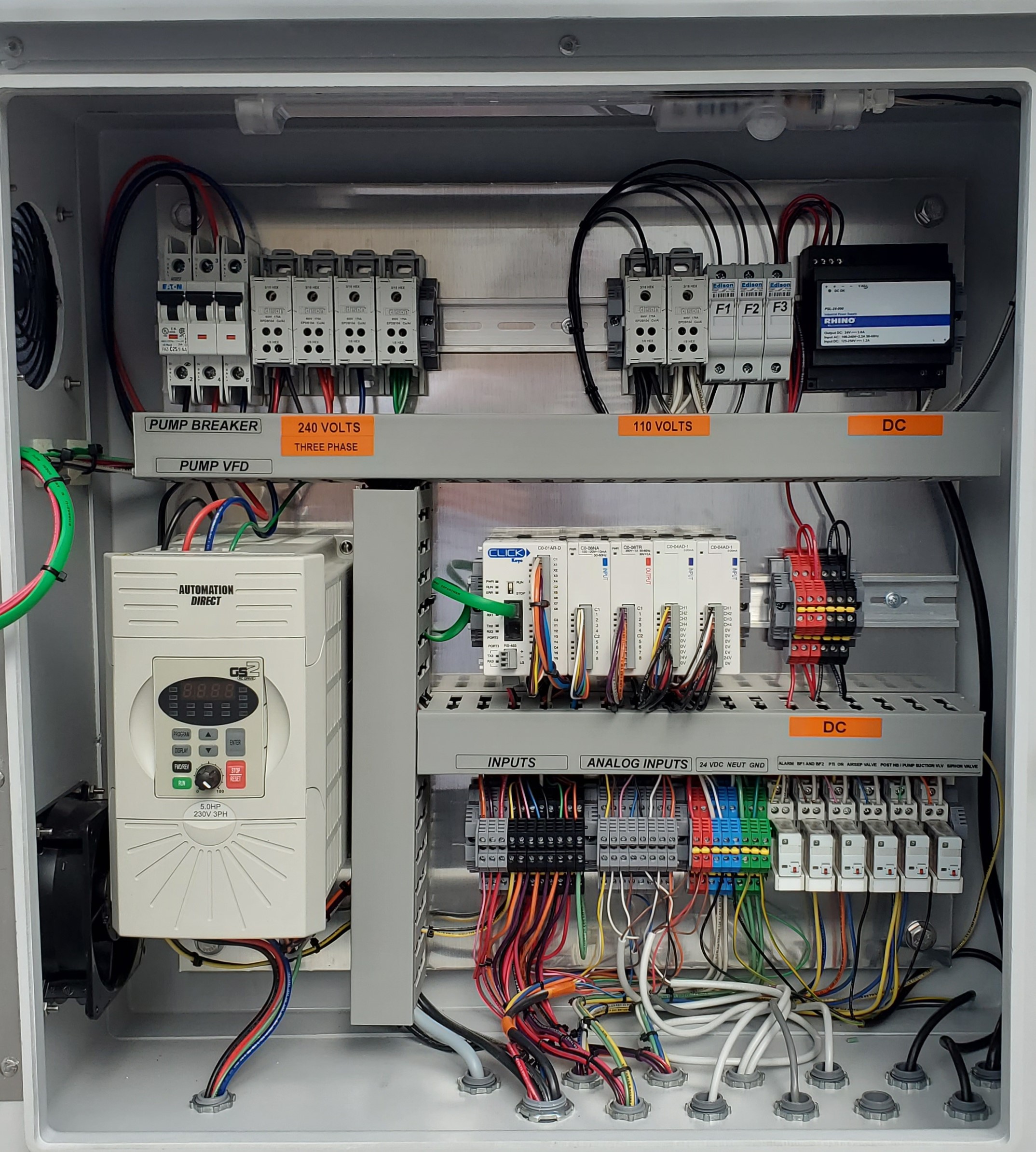

Fully automated variable control using PLC and VFD drive provides efficient use of oxidation

Nanobubble Technology

Self-generation of 93% pure oxygen *Feed compressed air required*

Dual self monitoring filtration

WRO3 NB System Specifications

WRO3 140 NB

Gallons Per Minute Up to 160

Max Treatment capacity Up to 10,000 gallons per day based on water quality

Dimensions 96” L X 48” W 75” H Stainless Steel Skid

Shipping Weight Approx... 1900 lbs

Construction 12 ga and 14 ga 304 Stainless Steel

Electrical 230 volt three phase power with neutral and ground 40 Amp Service

Controls Fully automated touch screen PLC with VFD control for all motors

Process Control ORP monitoring and control of ozone injection

Bag Filters Standard # 2 SS Bag Filters maximum 50 micron filtration

Oxygen generation 21 to 25 standard liters per minute at 45 to 55 psi on board

Ozone generation 140 g/H with a closed looped cooling system

Compressed air requirement Flow Rate: 18 SCFM Clean and Dry “Plant Air” (Class 5.6.4 per ISO 8573.1) Pressure: 90 psig (621 kPa or 6.2 barg) minimum- 3/8" connection

WRO3 280 NB

| Oxygen generation | 37 to 42 liters per minute at 45 to 55 psi, located separate from unit |

| Ozone generation | 280 g/H with a closed loop cooling system |

| Compress air rquirements | Flow Rate: 20 SCFM Clean and Dry “Plant Air” (Class 5.6.4 per ISO 8573.1) Pressure: 90 psig (621 kPa or 6.2 barg) minimum- 3/8" connection |

| Electrical | 230 volt three phase power with neutral and ground 60 Amp Service |