Articles & Videos

Tips, Tricks, & Helpful Hints

Get the latest insights and techniques on tank wash solutions to positively affect your P&L statement, working safer, with minimum environmental impact.

Take a little time to read some of our articles and watch some of our videos. Often they will be topics that you are familiar with. But every once in a while you may grab a pearl of wisdom with your name on it.

Did You Know About The 18° Rule?

Did you know, as a general rule, that increasing the temperature of a chemical reaction 18°F (10°C) effectively doubles the rate of that reaction.

Read MoreDid You Know – The Easiest Way To Break An Emulsion Is DON’T MAKE ONE?

That’s right. Don’t form it in the first place. This is especially applicable to operators cleaning tanks that contained lube oils and lube oil additives, because, once an emulsion is formed, skimmers, separators, and other oil separation equipment is basically useless.

Read MoreDid You Know That Cleaning Animal Fats Causes Foaming?

Did you know that fatty materials, such as animal fats and vegetable oils, will react with alkaline cleaning solutions and that this reaction both reduces the potency of the solution and can generate copious and troublesome foams?

Read MoreDid You Know That Stainless Steel Can Rust?

Did you know that stainless steel can rust? Stainless steels are primarily alloys of iron and chromium. When treated properly, the iron in the surface layer is removed and the remaining chromium is converted to chromium oxides.

Read MoreDid You Know That Acrylates Are “Easy-Cleans”?

Did you know that tanks that have been used to carry acrylic polymers and latexes are often cleaned with caustic and steam? Many acrylates are chemical compounds known as ESTERS. Esters are the reaction product of an organic acid (acrylic acid) and an alcohol such as ethanol or methanol.

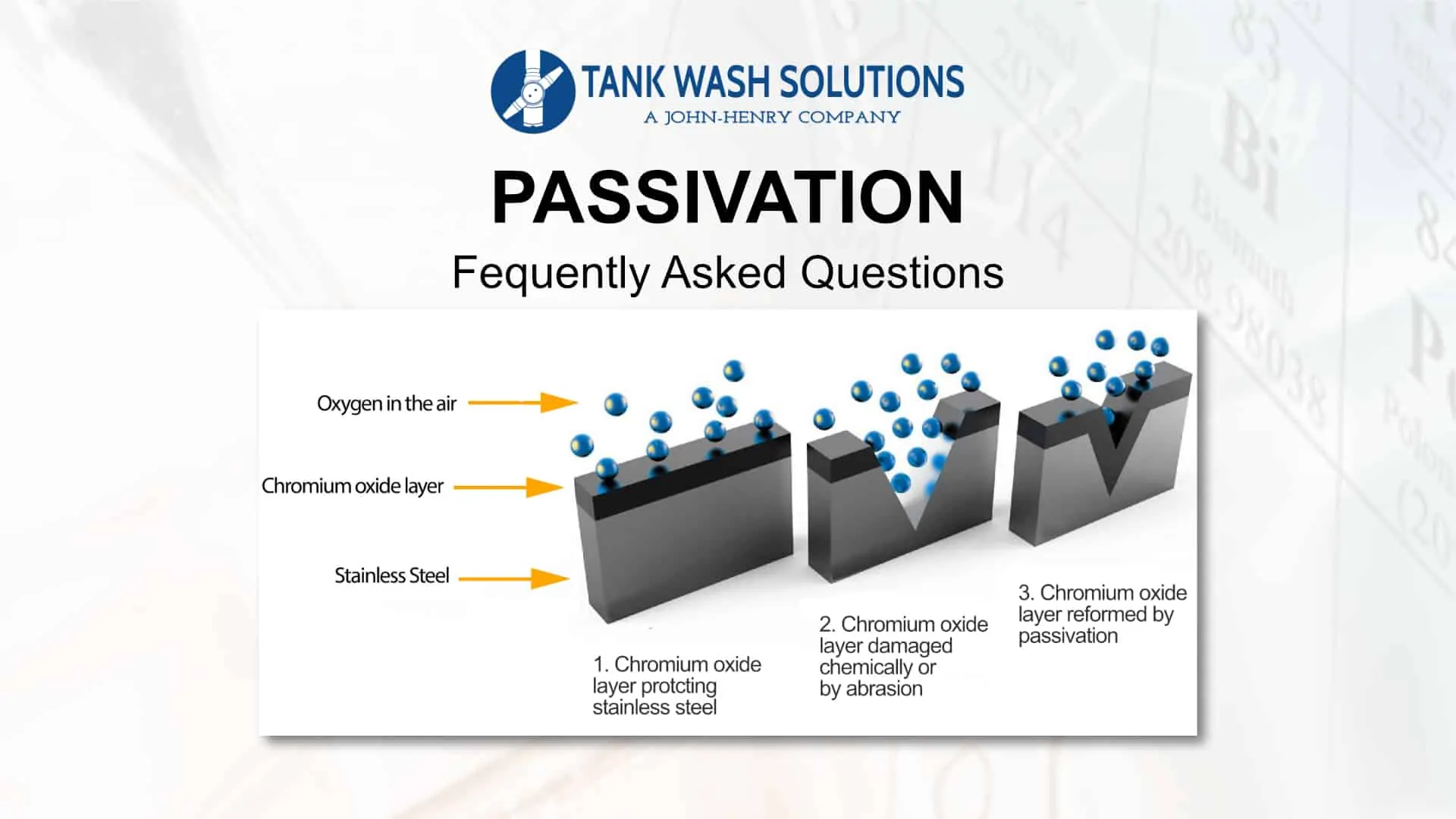

Read MoreFrequently Asked Questions About Passivation

Passivation is the chemical treatment of stainless steel with a mild oxidant, such as a nitric acid solution, for the purpose of enhancing the spontaneous formation of the protective passive film. Such chemical treatment is generally not necessary for the formation of the passive film.

Read More